Hybrid Bearings

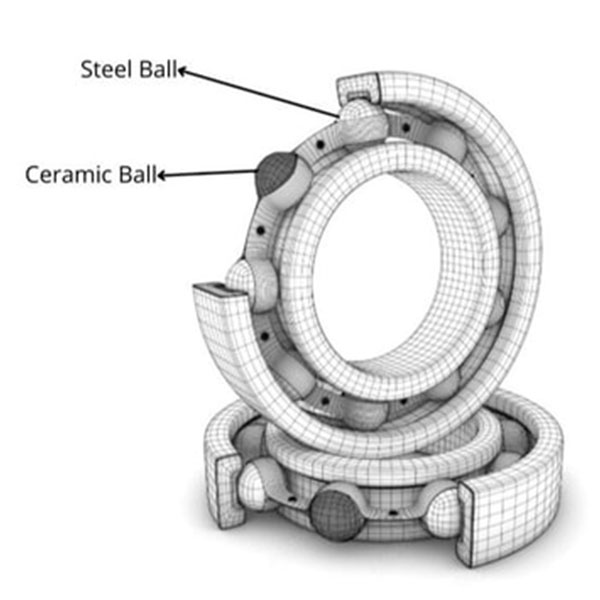

?Hybrid bearings are a middle ground between steel bearings & pure ceramic. Such bearings have metals inside and rings outside with ceramic balls. Because the lesser brittle metal rings become less prone to unexpected catastrophic loss under high speed/load, this arrangement allows for faster speeds than pure ceramic alternatives.

Considering the little design variation, hybrid bearings have very different needs than full ceramic bearings. Hybrid bearings, for example, require lubrication even though full ceramic bearings do not. Whereas the ceramic balls may continue to rub/ wear off the steel rings, hybrid bearings will manage with minimal lubrication smoother than steel bearings due to the reduced surface roughness & lightness of the balls.

Standard 52100 / Stainless Steel (S.S.) rings are combined with ceramic silicon nitride balls in hybrid ceramic bearings. Hybrid bearings, in spite of being effective electric insulators, have faster speeds potential (1.2-1.5 timeframe of spins) than steel bearings, and also provide longer lifespan, lower roughness, and lower power usage in most purposes than all-steel bearings. Electric engines/motors, satellite applications, performance race, extreme thermal equipment, deep water purposes and other applications are all using ceramic hybrid bearings.

Advantages And Characteristics

The advantages of hybrid bearings over equivalent-sized bearings with steel rolling parts include:

- Protection against damage caused by electric currents

Because hybrid bearings are non-conductive, they are suited for areas involving electric flux such as generators.

- Lubrication

When employing hybrid bearings at quite limited rates lubrication may be unnecessary. Nonetheless, because these bearings are frequently chosen for higher-speed purposes than full ceramics, proper lubrication is recommended. Highly precise hybrid bearings along with a high-speed cage can handle extremely high speeds, which is why they’re used in things like industrial machinery spindles, motors and many more.

- High Speed Capacity

A silicon nitride rolling component has a density that is 60% lesser than bearing steel. Decreased inertia and gravity lead to a higher acceleration and better handling during quick commencement and halt.

- Long-lasting efficiency

Hybrid bearings produce less frictional heat, which helps to lengthen bearing performance/ service life and re-lubrication frequencies, primarily at high speeds.

- Exceptional wear tolerance

Hybrid bearings are appropriate for severe circumstances and contaminated areas because silicon nitride rolling parts have a high strength. Whenever a hybrid version is chosen over a full ceramic model, the bearing’s corrosive resistance is also impacted. Despite the great corrosion resistance of the ceramic balls, the addition of metal rings, regardless if they are stainless steel, reduces the general degree of resistance to corrosion.

- Excellent bearing stiffness

Hybrid bearings have a high elastic modulus, which increases bearing stiffness.

- Less chance of smearing

The likelihood of smearing among silicon nitride and steel surfaces is decreased under insufficient lubrication situations like high speeds and fast maximum acceleration, or if there is not proper hydrodynamic coating.

- Lower chance of false brinelling

When hybrid bearings are exposed to vibrations, spurious brinelling between steel surfaces & the silicon nitride (Si3N4) is greatly reduced.

- Temperature gradient sensitivity is reduced

Silicon nitride rolling materials having a lower thermal expansions coefficient making them more stable over temperature gradients within the bearing and allowing for more consistent clearance adjustment.

Application

Hybrid bearings are mostly utilized in electric motors due to its strong dielectric conductivity of silicon nitride. Hybrid bearings are progressively being used in both rail transport drive ideas and manufacturing engineer rotary tables.

Expense, usage, and the hostile environment wherein the bearings would be utilized will mostly influence either ceramic bearings or hybrid bearings are chosen. Although your purpose may not necessitate ceramic bearings with the same severe temperature endurance as the ISRO Space Engine, having a deeper grasp of the various types can help you make a more informed decision.

In a Nutshell, Hybrid Bearings have the following features:

?

• Elements for rolling in ceramic

• Electrical resistance is high

• High speed capacity

Hybrid bearings are rolling bearings with distinct materials for the ball races & rolling components. With most situations, a hybrid bearing’s races are formed of roller bearing steel, while the rolling components are comprised of silicon nitride & high-performance ceramics.

References:

- https://www.skf.com/in/products/rolling-bearings/engineered-products/hybrid-bearings

- https://www.machinedesign.com/mechanical-motion-systems/article/21837372/whats-the-difference-between-ceramic-and-hybrid-bearings

- https://www.krw.de/en/products/application-optimized-bearings/hybrid-bearings/

- https://www.ortechceramics.com/product-category/ceramic-bearing/hybrid-ceramic-bearings/